Instruction

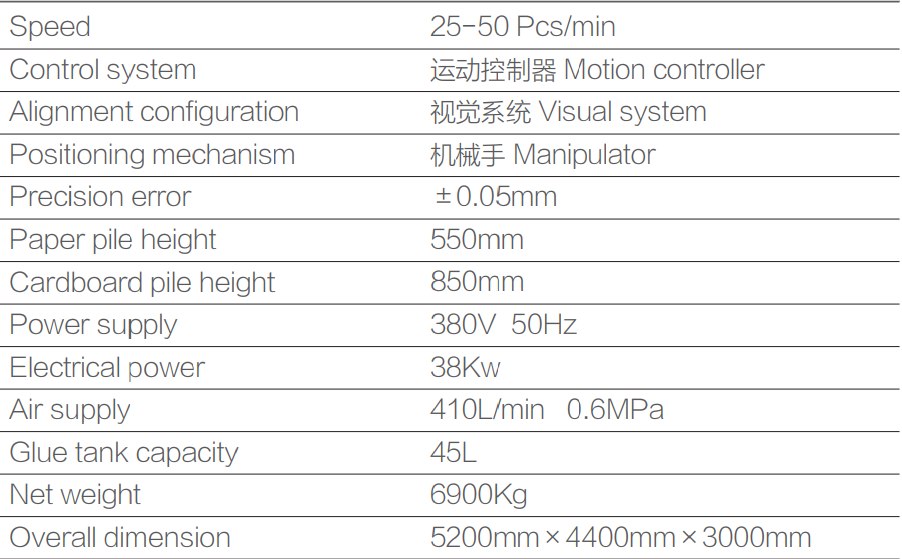

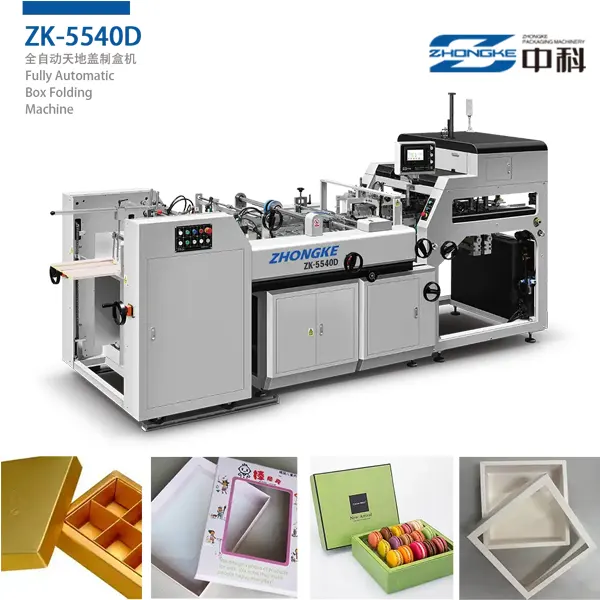

Rigid box making machine ZK-3525D adopts double-station forming mechanism, servo control system, programmable motion controller system, vision + robot positioning system, and man-machine interface intelligent system to realize intelligent operation functions, digital adjustment methods and parameterized function settings. It can achieve high positioning accuracy of the machine, easy adjustment of changing specifications, more stable operation, more stable operation and smoother movements. Automatic paper feeding, gluing, cardboard four corners taping, feeding, edge covering, full ear folding, forming and shaping of the finished box are completed in one operation. The use of double-station mechanism greatly improves the production efficiency of this machine, and the production speed can reach 50 pcs/min.

Application

It's applicable to the production of high-end rigid boxes with big orders, such as electronic product packaging boxes, mobile phone boxes, jewelry boxes, cosmetic boxes, watch boxes, gift boxes, etc.

Note

The size of the box is restricted by the size of the cover paper.

Online Viscometer system(optional).

The company does not provide air compressors.

Several factors that affect the speed of the machine: raw materials, glue and operator proficiency.

Due to continuous innovation in product design, the above data is for reference only; and are subject to change without notice.

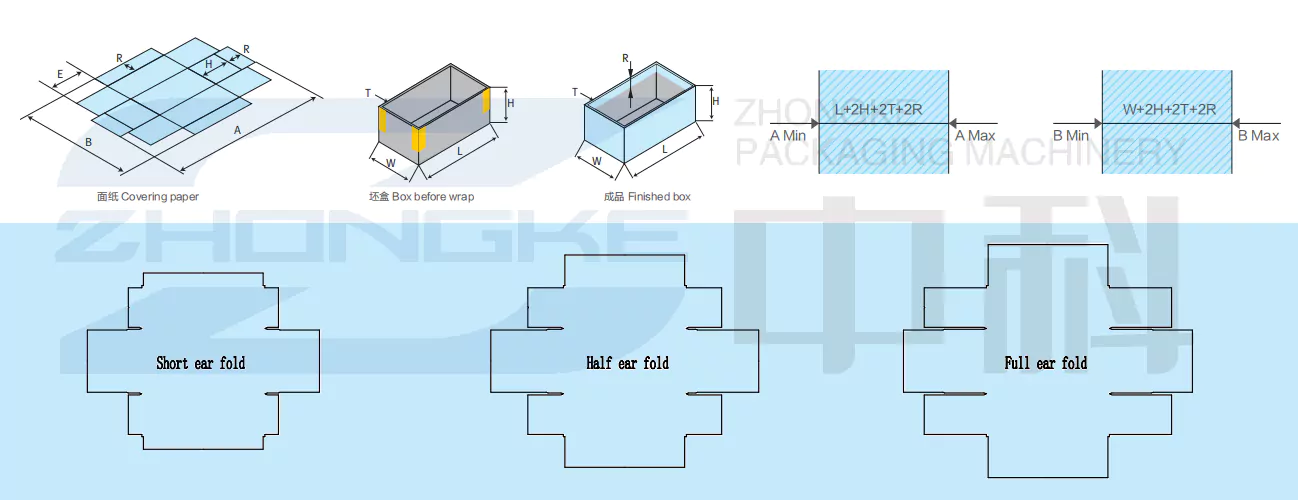

Box Craft Drawing